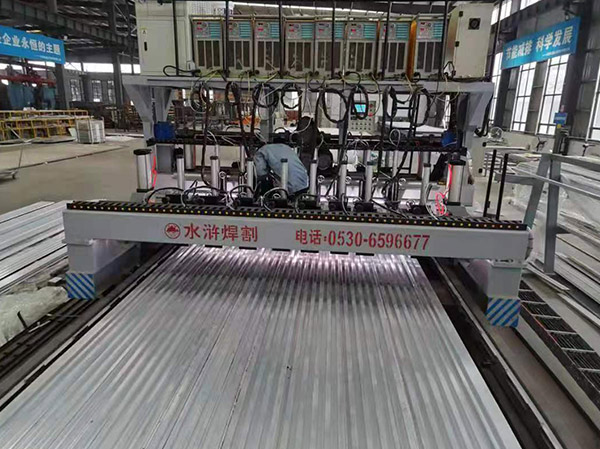

Refrigerated Truck Aluminum Bottom Plate Automatic Welding Machine

The gantry-type refrigerated truck aluminum bottom plate welding machine is a special welding equipment specially developed for the welding of refrigerated truck bottom plate profiles. It is equipped with multiple guns for simultaneous welding of multiple welds and long welds on the workpiece, which effectively reduces production costs, improves welding efficiency, and stabilizes welding. quality....

Gantry type refrigerated truck aluminum base plate welding machine

The gantry-type refrigerated truck aluminum bottom plate welding machine is a special welding equipment specially developed for the welding of refrigerated truck bottom plate profiles. It is equipped with multiple guns for simultaneous welding of multiple welds and long welds on the workpiece, which effectively reduces production costs, improves welding efficiency, and stabilizes welding. quality.

In order to facilitate the operation of the equipment and the flexibility of use, the overall control adopts touch screen + PLC control. The welding gun tracking method can use mechanical tracking and laser automatic tracking of the weld seam position for welding. The welding operation is simple and the weld seam tracking position is accurate.

This machine uses multiple AC square wave argon arc welding power sources to start arcs and weld at the same time (it can also start welding individually). In order to ensure the reliability of arc starting, this machine is equipped with a synchronous arc starting device to ensure the arc starting of multiple gun heads for simultaneous welding. Success rate.

leave a message

Thank you!

Please enter your email